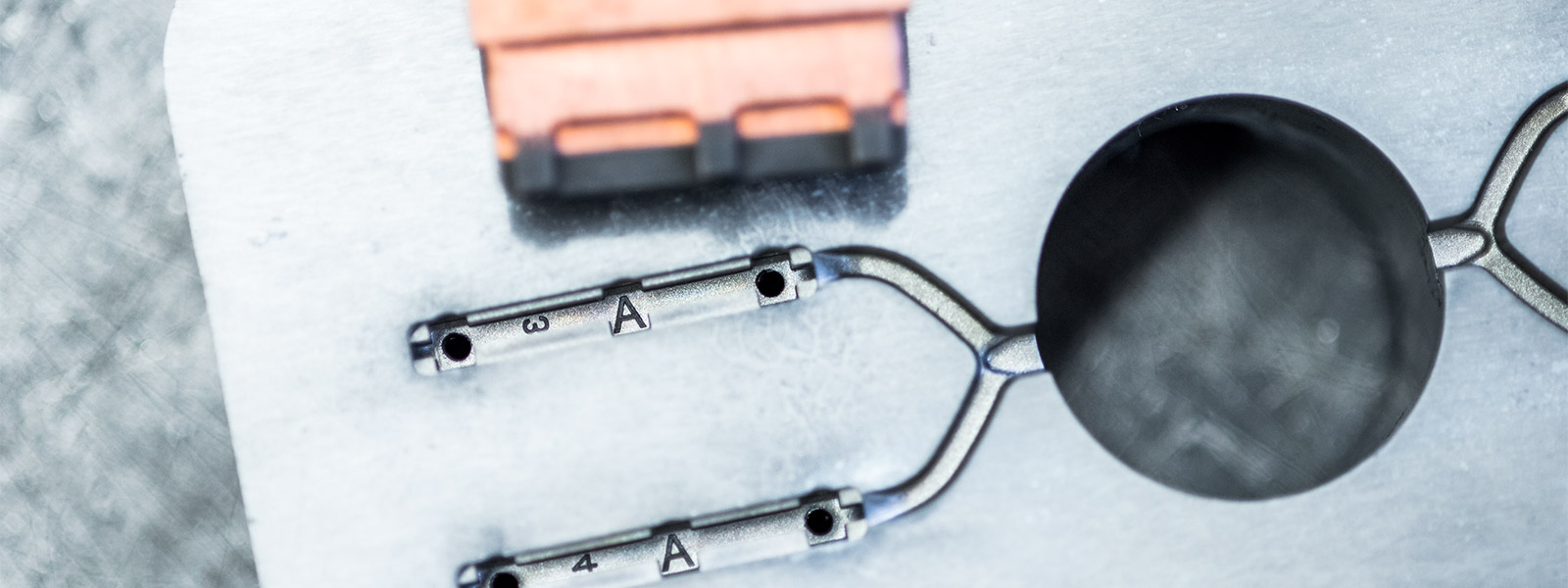

Zinc Die Casting

Complex geometries and quality finishing.

As specialists in zinc die casting, we have been meeting the highest standards of precision and quality for over 40 years. At our Velbert location, 14 hot chamber die casting machines with clamping forces of 20 to 200 metric tons produce zinc die cast components with weights from 0.5 to 2000 grams. We handle medium to large production runs in accordance with a huge variety of different customer requirements.

We stand out from the competition thanks to our technical knowhow in collaboration with our sister company Druckguss Westfalen and our expertise in surface finishing and plating.

Minimum subsequent machining for your components – guaranteed

Using zinc it is possible to cast exceptionally intricate, thin-walled and technically demanding parts to very high precision. Subsequent machining is rarely necessary – provided that you work with specialists who, like Druckguss Westfalen Behringer, have vast experience in zinc die casting and apply the highest standards of quality. In-house tool design and advance casting studies permit near-zero tool defects. In this way, we can deliver your products as fast as possible and guarantee a long mould service life.

Chrome or nickel plating for long-lasting quality

We additionally offer high-quality surface finishes with a very wide range of surface improvement options. This is our speciality. Zinc die cast components are ideally suited for electroplating. Alongside standard coatings for corrosion-resistance, we also provide special finishes such as chrome plating, nickel plating, CDP or powder coating. These finishes meet the highest quality standards for that premium look and feel.